Craftsmanship

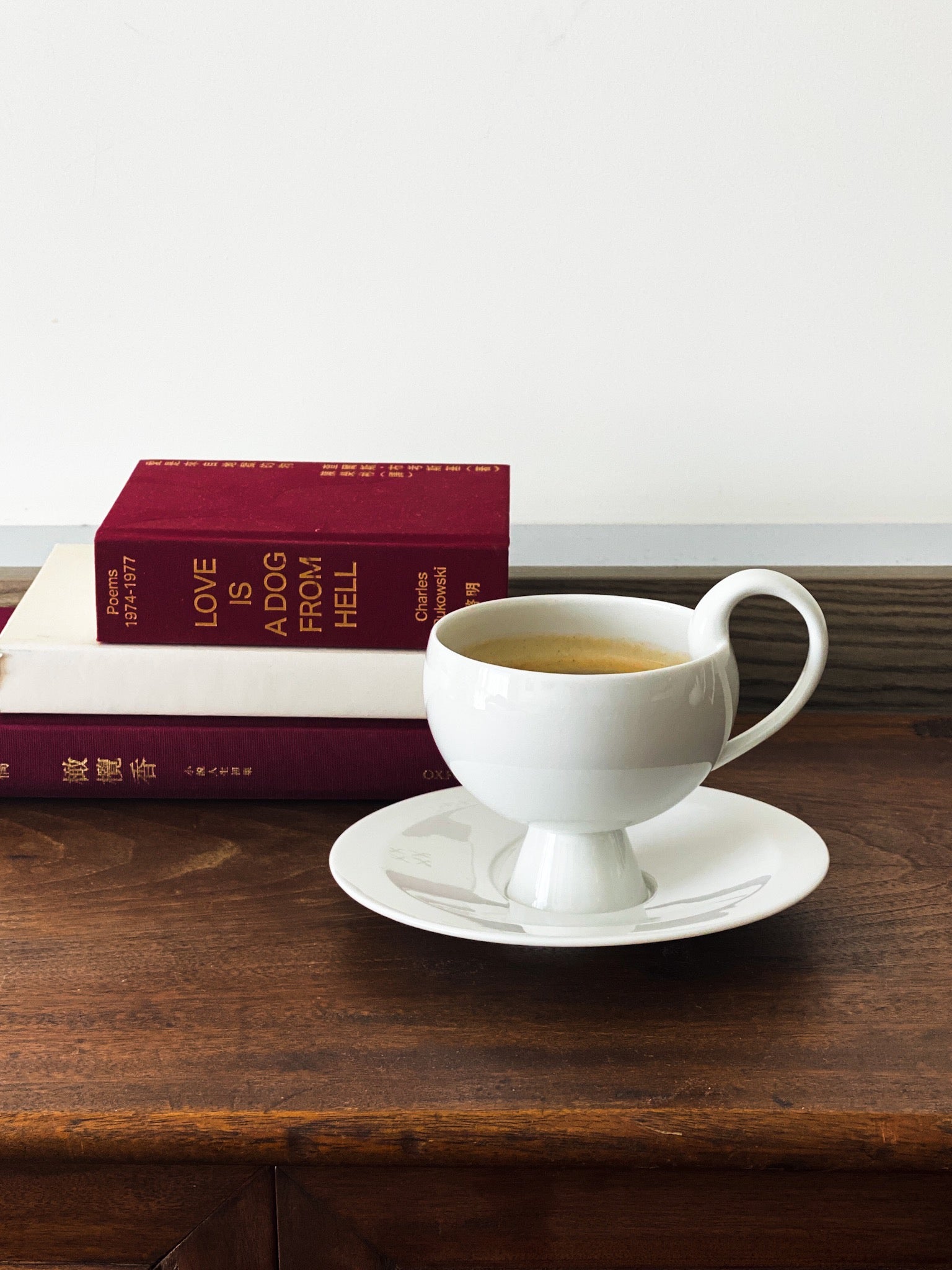

The porcelain craft that gradually matured during the end of the Eastern Han Dynasty has maintained its chimney-like cylindrical shape for 1,800 years, showcasing a subtle imagery. Its gorgeous and elegant beauty requires the strokes, lines, colors, and patterns of the painted craft to decorate it.

Facing modern aesthetic trends, such as the art nouveau and art deco movements, which have influenced materials used in architecture, interior design, furniture, and daily necessities, porcelain shape has remained unchanged.

The unchanging imagery of porcelain over thousands of years has its own difficulties to overcome, and this has limited the development of porcelain's form and aesthetics. During high-temperature firing of porcelain clay, the individual particles of porcelain clay begin to fuse together, resulting in over 15% shrinkage, which causes cracking in porcelain. Therefore, round shapes are considered safe. Additionally, high-temperature porcelain clay begins to densify and vitrify, causing the clay to soften and collapse, leading to deformation.

Heinrich Wang and NewChi Artisans broke through the obstacles of porcelain craftsmanship that had persisted for thousands of years. From then on, porcelain has a brand new look.

The diversity of beauty is always trapped by techniques, and porcelain is one of them. Due to the fateful phenomenon of high-temperature porcelain and densification of porcelain clay, shrinkage, cracking, softening and deformation, etc., the development of porcelain modeling is limited. It is difficult to keep pace with the so-called beautiful rhythm of time and space changes. In addition to classical gorgeousness and elegance, the possibility of beauty is there in porcelain is always suspenseful.

- Founder Heinrich Wang

Know about Heinrich WangCraftsmanship

A Breakthrough Story

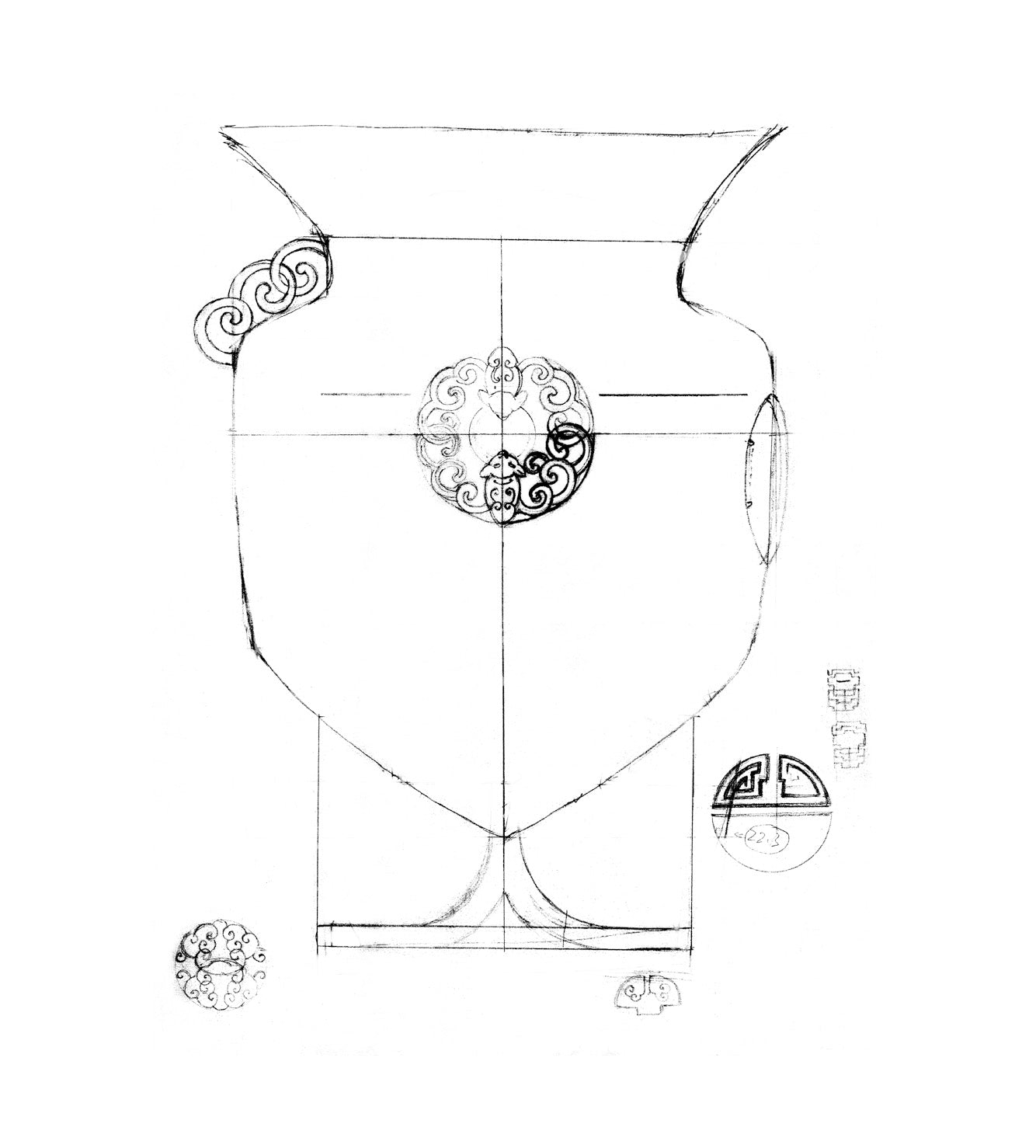

NewChi design drawings are different from the traditional round and cylindrical shapes. In order to produce finished products, he must face a 15% high proportion of shrinkage and softening phenomenon. Suitable scaffolding must be erected around the clay embryo to support or surround it to prevent the porcelain from distorting or deforming during high-temperature firing. The design and production of the scaffolding require precise calculation and disassembly, and each one must be individually modeled to achieve precise and delicate shaping. At the same time, during the shaping process, it is necessary to avoid the temperature reaching 200-300 degrees Celsius with just a small amount of fire, which can cause uneven heating of the single clay embryo. Compared with the general 9 hours to the high temperature point, NewChi needs to fire in stages for more than 25 hours. Due to the unique shape, the annealing and cooling time also needs to be extended. Although everything is carried out according to the standard process, there is an extremely low success rate.

-

Porcelain clay shrinks 15% less after sintering.

-

Distortion after firing under high temperature.

Design

Creates different design sketches based on different themes.

Prototype Sculpture

Enlarging the three-view dimensions of the design by 15%, and sculpting a prototype using plaster, wood, or oil-based clay.

Mold Making

After finalizing the prototype design, a plaster mold is made using the prototype to facilitate slip casting and obtain the clay body. In order to prevent difficulties in demolding various chamfers, the prototype must be disassembled into various components and each component is individually made into a mold in sections.

Casting

After drying the plaster molds of the prototype, they are filled with porcelain clay. Because the plaster molds have water absorption, after about 10 minutes, the plaster absorbs water, and the slurry in contact with the plaster mold forms a thin wall of clay. The plaster mold is then dismantled to obtain a wet and soft clay blank with complete shape and delicate texture. For some medium to large works, the plaster mold can weigh up to 70 kilograms, and at least three people are needed to work together for each filling and pouring.

Shaping

After assembling the various components of the prototype, the clay model is completed. Then, the joints and uneven areas along the split lines created by the mold are carefully trimmed and repaired by hand using tools such as sandpaper, sponges, bamboo sticks, and brushes. Each layer is finely polished to achieve precise lines and a smooth surface. During the shaping process, when the clay is still wet and soft, a support structure is used to protect it from deformation. The clay model is then air-dried thoroughly before being fired in the kiln.

Firing

After the dried and completed shape, the clay and the holders are placed in the kiln, they are fired at a high temperature of 1300°C in the kiln. The shrinkage of the clay from forming to firing is about 15%. After being fired at high temperature, the holder cannot be reused. Each piece of work takes up a limited amount of space in the kiln due to the space occupied by the holder, making the process time-consuming and labor-intensive.